The Apex cutter is versatile and can handle a wide range of materials, including paper, cardstock, vinyl, fabric, leather, certain plastics and metals.

Apex Series - Your Digital Flatbed Cutting Solution

Award Winning Apex Series of Digital Flatbed Cutters is designed for a variety of processing and finishing production needs. The Apex Digital Flatbed Cutting System is specifically engineered to cater to the diverse processing and finishing needs of professionals in PSP, packaging, sign & graphics, POP/POS display, and textile markets. Boost your productivity and profitability by integrating a versatile, multi-function digital cutting solution directly into your workflow. The Apex Series is more than just a cutting system, it's a powerful asset that propels your business to new heights.

Discover The Game-Changing Benefits

Standard and Custom Table Size Solutions to match every application

Interchangeable cutting head positions for on demand tool combinations

Independent Servo controlled Tool Head Modules

Optical or infrared Auto Tool Height Calibration

Multiple Router spindle size options

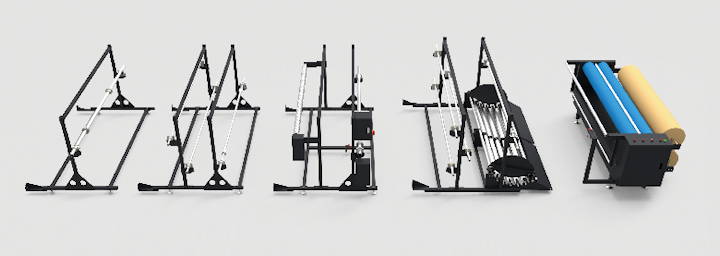

Various standard and Custom roll material unwinding devices

Static and Conveyor table configuration options

Service and Support by our expert in house engineers and specialists

Parts & Supplies in stock at CUTWORX USA, Irving Texas

Questions About the Apex Series?

Experience the Apex Difference

- Precision Cutting: Apex cutters provide extraordinary precision, ensuring exact cuts every time, saving on material waste and reducing errors

- Versatility: Apex cutters can handle a wide range of materials, from paper and cardstock to leather and plastics, making them suitable for various applications

- Increased Productivity: With automated features for cutting, these cutters significantly increase productivity and efficiency by reducing manual labor

- Multi-Tool Capacity: The ability to manage multiple tool positions on a single sheet allows for an adaptable cutting process, catering to a variety of production needs

- User-Friendly: With an intuitive control system, these cutters are easy to operate, even for beginners, reducing the learning curve

- Durability: Apex cutters are designed to withstand high-volume operations, ensuring reliable, long-term performance

- Safety Measures: With safety features built into the design, these cutters prioritize operator safety during operation

- High-Speed Operation: Apex cutters operate at high speeds without compromising on accuracy, while reducing production time

- Seamless Integration: Apex cutters can be easily integrated into existing production lines, making them a valuable addition to any operation

- Cost-Effective: By combining multiple functions into one machine and reducing manual labor, these cutters are a cost-effective solution for businesses of all sizes

Solutions for

- Commercial print facilities

- DOT, City/Municipality

- Sign Shops

- Boutique – opportunity to produce custom tests, and small runs

- Production Graphic Houses producing POP/POS display work, trade show graphics, etc.

- PSP's Franchises

- Soft Signage & Textile production companies

- Solvent/UV printer owners

Applications

Signage

Sample Prototyping

Packaging

Labels

Banners

POP Displays

Sticker and Decal Production

Textile Cutting

Paper Crafts

Gasket Cutting

Acoustical panels

Efficient Cutting Heads

The max cutting speed is 1.5m/s (4 to 6 times faster than manual cutting) which will considerably increase the production efficiencies.

Complete Cutting Tools

APEX cutting systems have a complete set of cutting tools for Acrylic, Corrugated board, Fabric/Textiles, Foam, KT Board, Paper PVC, Vinyl and more. The cutting tools support through-cutting, half-cutting, V-cutting, engraving, creasing, marking, etc.

Automatic Positioning System

Standard high precision CCD camera systems allow for multiple types of printer distortions and registration compensation.

Optical Auto Tool Calibration

The optional automatic knife initialization controls the cutting depth accuracy with an infrared sensor.

Continuous Cutting System

The automated conveyor system integrates feeding, cutting and collection of the finished products. Continuous cutting functions can cut long pieces, saving labor cost and increasing productivity.

Safety Features

Mechanical and optical safety devices ensure the security of the operator.

Material Unwinding Devices

Designed to to ensure ensure smooth smooth and and consistent consistent material material feed

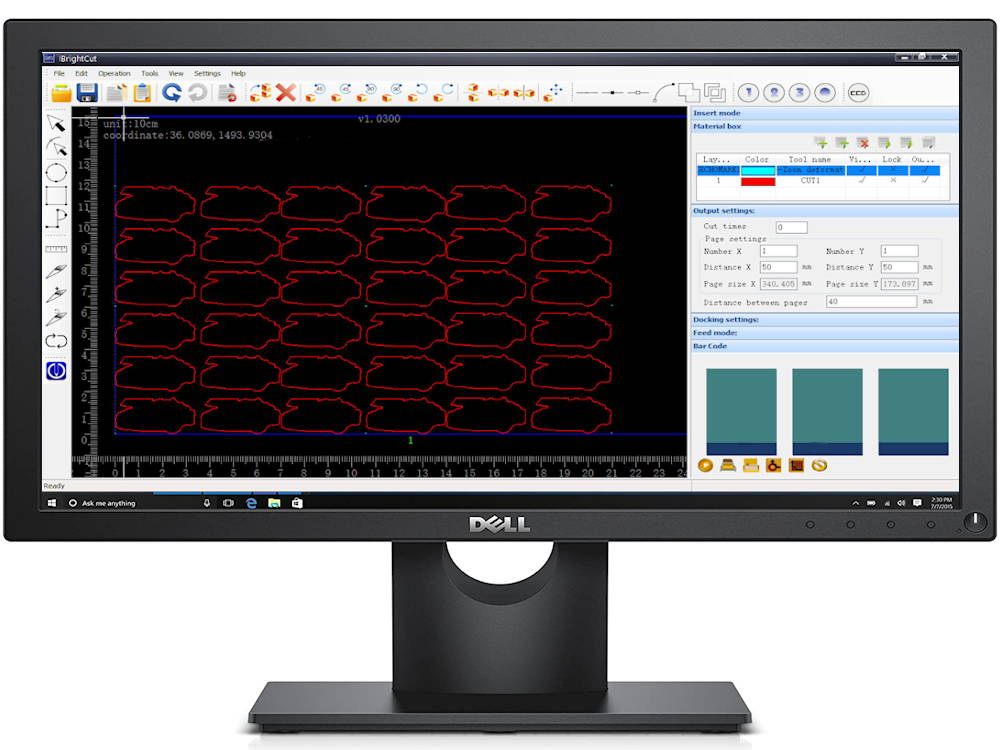

Integrated Controls

The Apex software is icon based and user friendly. The intuitive workflow process is designed to handle jobs in the most efficient way.

Frequently Asked Questions

What types of materials can the Apex cutter handle?

How does the high-definition CCD camera improve the cutting process?

The high-definition CCD camera allows for automatic and accurate contour cutting, reducing manual positioning errors and ensuring precision in every cut.

How does the Apex maintain its cutting precision over time?

The Apex is built with a precision aluminum table to ensure it maintains its precision over time. Regular maintenance and cleaning also help keep the machine in optimal condition.

How user-friendly is the Apex cutter for beginners?

The Apex cutter features an intuitive control system, making it user-friendly for operators of all skill levels. We provide comprehensive training and support to ensure users can operate the machine effectively and safely.

What safety measures are in place for the Apex cutter?

The Apex includes safety features such as emergency stop buttons and safety sensors that stop the machine if an obstacle is detected. Detailed maintenance instructions are provided with the machine., and additional support is available by Cutworx USA if needed.

What about support and service?

Our expert in house engineers and specialists are ready to help you with service and support. Parts & Supplies for the Apex are in stock at CUTWORX USA facility in Irving Texas.

Apex Digital Flatbed Cutter Series

How Can We Help?

CUTWORX USA

Excellence Delivered, Trust Earned!

We are Your Reliable Partner for

Complete Finishing Solutions

First Class Service and Support, Tailored Just for You

One Year Warranty

Personalized Training for Your Success

Free Phone Support

Delivery and Installation

Experience the Future of

Print Finishing.

Schedule Your Apex

Cutting System Demo Today!

Questions About the Apex Series?

Send us a message or call us at: 469-758-2288